M8Tyres

I decided that the hard plastic tyres on the model were not suitable for the conversion. After looking around for suitable replacement I could not find anything of a suitable size.

So I had to make my own tyres.

Researching the process I came upon the silicon moulding system. Where I had to make a two part mould of the original tyre and then cast new tyres using this mould.

I looked at replacing the wheels and tyres with after market items but could not find anything that was the correct diameter or had the tread pattern of the original, that meant I had to change the hard plastic tyres for softer rubber ones and mould them myself, this is a summary of the process.

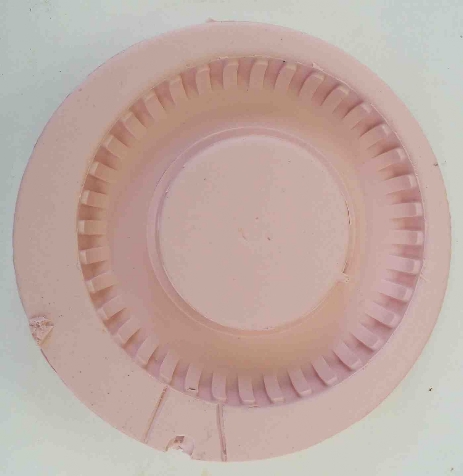

In the pictures above, I have supported the original tyre just off the bottom of a round plastic tub, then poured the silicon in until it rises to the join line half way up the tyre. The second picture shows the tyre removed from the lower mould (do not do this until the whole process is complete!). The tyre has been sprayed with release wax. Then make the top half of the mould. The mould needs to be left to dry for 7 days before use.

The top half is pictured on the left, I have added two air channels to release air as the liquid rubber is injected in. I have not cut the fill hole yet. The tub needs three holes drilled at the air holes and fill hole locations.

To inject the rubber prop the mould up so the air channels are at the top and use the syringe to inject the rubber through the fill hole, pour rubber into syringe then insert plunger and inject, three times, until rubber comes out of the air holes.

The next pictures shows a tyre at the demould stage (1.5 hours after pouring).

I am just about to remove it from the mould.

Tyre after trimming the flash off, as you can see a few air bubbles we trapped which have made pits in the tread, hopefully I can improve the process to remove them.

Finished tyre on the wheel.

Costs :-

supplier www.mbfg.co.uk

Polytek Poly PT Flex 60 Liquid Casting Rubber 500g = £16 + 2kg = £48

Polycraft GP-3481-F RTV Silicone Mould Making Rubber 1.1kg Kit Shore A27 £20

Polytek Polycolor Dye / Pigment - Black 20g £6

MAC WAX Mould Release Spray for GRP & Silicone 400ml £11.50

100ml plastic syringe £3.60

Total £105.10

Each tyre cost £17.51

The first £16 of casting rubber I used for testing the process, so if I exclude it's cost gives £14.85 per tyre

I used roughtly 330g of rubber per tyre, so 6 = 1980g so the 2kg kit was just enough. Measured by weight.